I was running low on medium spikes and decided to try micro spikes again. They certainly have their deficiencies, but I really like the look.

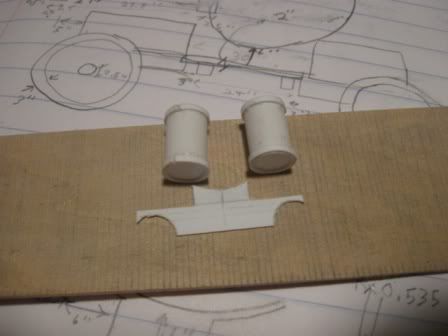

Here are some medium spikes...

Here are some micro spikes...4 per tie...

I definitely like it much better.

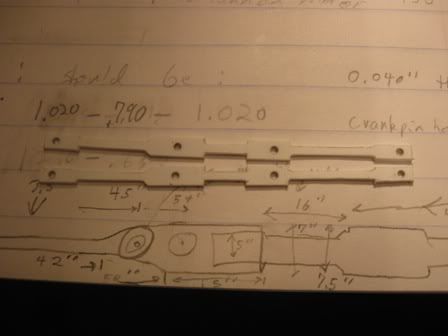

I also ran out of ties, and so I began cutting down switch ties. I decided to keep the scrap materials as I've flirted with adding a bit of On2 at some point...maybe just 12" of track below my trestle.

Today, I stopped by my LHS and picked up more bridge supplies, a DSP&P push car!!!, and a piece of N scale Code 55 flex track. I snipped off a couple lengths of the Code 55 rail and spiked it to the scrap ties using micro spikes...On2 track! I might make a provision for several feet of On2 in my town. I won't be adding the On2 track now, just adding the necessary supports for it.

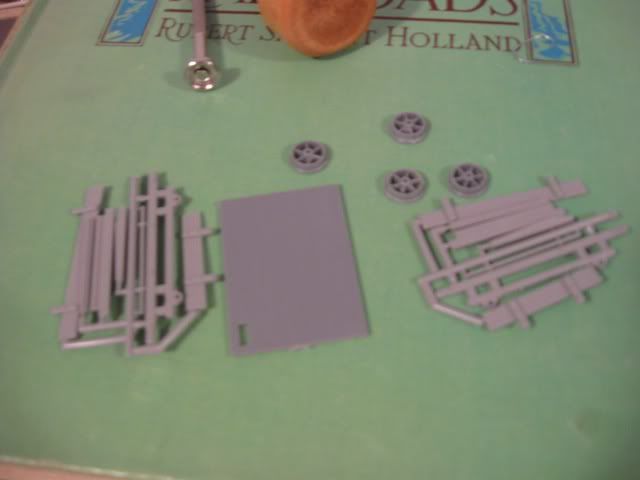

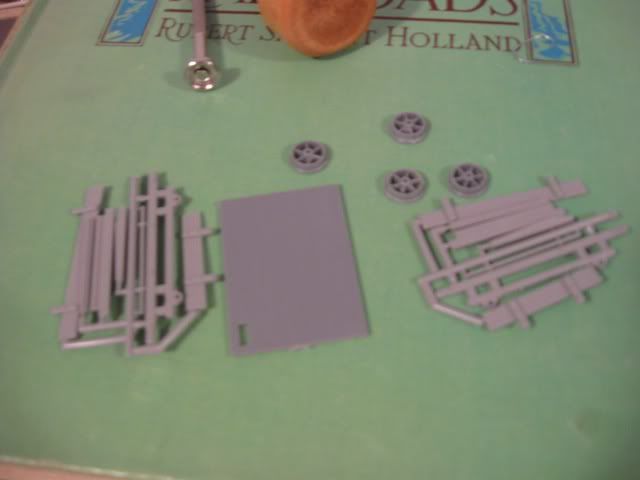

Here's the DSP&P push car kit...

It'll look great with my PSC hand car.

An On2 Grandt Line Gilpin Gold Tram car sitting on Coronado's Gilpin On2 trucks...sitting on the On2 test track. The spikes, gauge, and tiny rail work fine together.

Here's a comparison of N scale flex track, HOn3 track I laid when I was 16, the new On2 track, and On3 track.

Here's the same but with a piece of HO track sitting there to give an idea of how On30 looks alongside On2 and On3. It is a terrible stand in for On2!

I have a B-man 8ton On30 porter which I'll convert to On2, and later I'll also add a 2-truck shay. I don't care much for Maine Porters...and I think that the gorgeous Maine 2-6-2 is too large for what little track I'll have. But I won't be adding any On2 for some time.

I really like the look of the micro spikes...and I presume that I could combine them with some tie plates I have. My track would look great, but that would be a ton of work. I'll need to find either better micro spikes or a better set of pliers for spiking them down. With medium spikes, I have other tools which I use instead of pliers.

I also textures some of the ties and gave them a little bit for India ink & alcohol staining.

I've built a model of my model railroad and picked up some cheap clay to experiment with the scenery which I'll be starting soon...

It is 1/12th scale.