So, I cleaned up my basement workspace and it is now the home of my resin work.

I've generally found that the ultimate table protector is garbage bags. Neither silicone rubber nor polyurethane will stick to it...and it is a material we always have in the house.

Since I now have a home for it, I managed to prepare some new molds and make a few test castings.

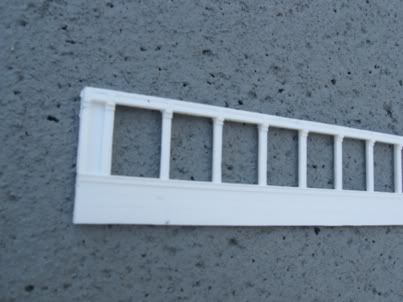

This is the second casting from the interior wall mold. I like it. I may add coat hooks above each seat, per the prototype in the early days, using brass wire.

And this is an out of focus view of the first OR&L roof casting. It is a beauty. There is one air bubble along one of the ends which I'll probably fill for durability, as well as a portion of the sheathing which is a little thin and might get reinforced. The other defect is the swayback. While a swayback is a coveted feature amongst many model railroaders, I am not in that camp. I ought to be able to fix it with a little heat. The detail of the master has been nicely captured in this resin casting. In order to get one of these cars ready by next weekend, I may just fabricate a frame in styrene for the first car...and do the master & mold later.

Currently, a DSP&P 34' passenger car roof is curing in my other roof mold.

No comments:

Post a Comment